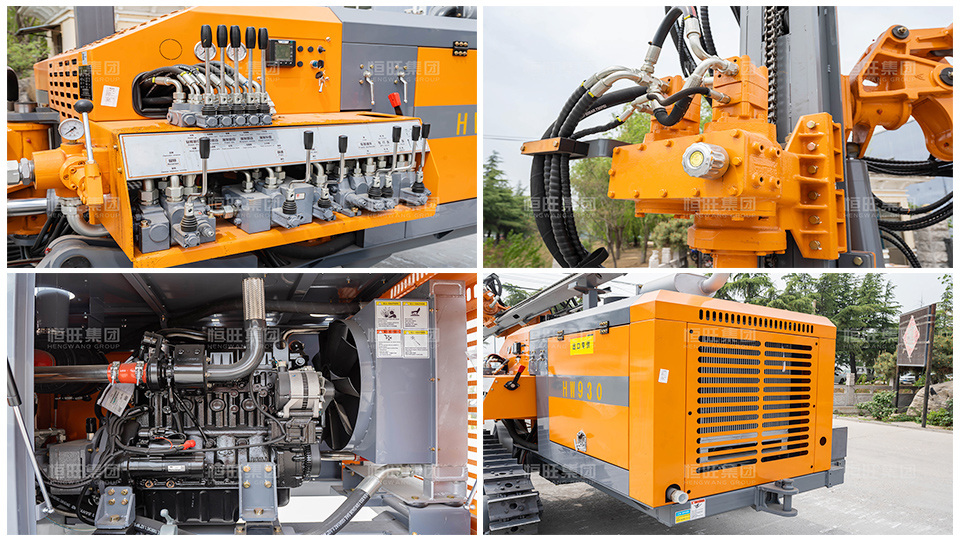

In mining and rock blasting projects, DTH Blast Hole Drill Rigs have become the preferred equipment due to their exceptional drilling efficiency and stability. Whether in open-pit mines or tunnel construction, DTH Blast Hole Drill Rigs can quickly complete high-precision boreholes, significantly improving operational productivity.

1. High-Speed Drilling Saves Time

DTH Blast Hole Drill Rigs utilize advanced percussion drilling technology to easily penetrate hard rock formations. Compared to conventional drills, DTH Blast Hole Drill Rigs achieve faster penetration rates, with a single rig capable of drilling 50-100 meters per day, drastically reducing project timelines.

2. Adaptability to Challenging Terrains

From steep slopes to narrow tunnels, DTH Blast Hole Drill Rigs operate flexibly. Their modular design allows for easy transport and assembly, making them ideal for remote mining sites or harsh working conditions.

3. User-Friendly Operation & Low Maintenance

Modern down-the-hole blast hole drilling rigs feature intelligent control systems, enabling operators to master them after short training. Routine maintenance only requires periodic checks of lubrication and drill bit wear, lowering operational complexity.

4. Cost-Effective with Quick ROI

Investing in a DTH Blast Hole Drill Rig typically pays for itself within 6-12 months through project returns. Their durability ensures long-term cost efficiency, outperforming equipment rentals—especially for mid-to-large-scale mining companies.

5. Safe & Reliable Performance

DTH Blast Hole Drill Rigs incorporate enclosed designs to minimize dust and noise pollution. Consistent drilling accuracy also optimizes blasting results, reducing hazards like misfires.

Conclusion

DTH Blast Hole Drill Rigs are transforming traditional mining methods by delivering efficient and safe blasting solutions. Whether for metal mining or quarry operations, choosing DTH Blast Hole Drill Rigs guarantees enhanced productivity.

Road Leveling Bulldozer: The Core Guarantee for Efficient Road Construction

Road Leveling Bulldozer: The Core Guarantee for Efficient Road Construction

Off-Road Forklifts_ A Powerful Assistant for Complex Field Operations

Off-Road Forklifts_ A Powerful Assistant for Complex Field Operations

High-Load Off-Road Forklift: A Powerful Tool for Heavy-Duty Operations in Complex Environments

High-Load Off-Road Forklift: A Powerful Tool for Heavy-Duty Operations in Complex Environments